Stifel, the indigo gold rush

Sought after by collectors from around the world, the pieces stamped by Stifel are nowadays sold for a fortune. The Stifel brand is recognized for its wonderful history that explores a fabric maker’s previously unknown production methods and the fabrics’ unbelievable durability. To understand the phenomenon, we must go back in time, to the banks of the Ohio River, where we discover the small town of Wheeling. A story by Eric Maggiori and Gabriel Cnudde.

A pair of overalls. 1,281 dollars. A jacket. 1,097 dollars. Two Buddy Lee dolls wearing coveralls and overalls. 3,338 dollars and 3,010 dollars. Two children’s playsuits. More than 300 dollars each. A paperweight mirror? 560 dollars. Sold on eBay in Late 2018, what do all of these have in common? They are stamped with the Stifel logo. This means they are easily identifiable: Stifel garments are indigo blue, with thin white stripes. A few years ago, during Inspiration LA’s 2016 show, a Japanese buyer purchased an early 1900’s Stifel jacket for 8,500. The prices seem crazy, but in the US and Japan, the price of Stifel clothing is not really surprising to anyone that knows its story. In 2017, the Hundred Buyers shop, in Tokyo, posted a picture on its Instagram account of deadstock Stifel overalls, dating back to the early nineteenth century. The price? “38,000 dollars. It’s very expensive, but very rare. Nobody has that”, the shop’s boss explains. To understand how and why such seemingly simple indigo clothing items have become so expensive and sought after, we must immerse ourselves in a time of US history where all dreams were permitted, nearly two centuries ago.

Wooden shack and Calico

1833. The first mines have now been open for four years in Georgia. The United States is welcoming boats on a daily basis, filled with immigrants coming to the land of Uncle Sam to chase the dream promised by many. The disillusioned of the Old Continent continue to converge in increasing numbers to write all together, the great story of the United States. They are coming to find land, gold, and above all, a better life. Among the first immigrants, we find a certain Johann Ludwig Stifel. Born in 1807 in Neufen, Germany, the apprentice dyer sets foot in Baltimore, Maryland, before heading to Bethlehem, Pennsylvania to spin wool. “According to the myth, Johann Stifel walked bare foot all the way to Wheeling in 1834”, tells Rick Morgan, the director of the Stifel Fine Arts Center of Wheeling, a small town of 28,000 inhabitants in West Virginia.

With the only ten dollars he has in his pocket, JL Stifel buys a batch of cotton fabrics and opens up a small dyeing factory. “It was a small wooden shack. The business was going so well that less than a year later, JL would open a big Calico shop at the junction between the main road and ninth street”, Rick then explains. Calico, a fabric originating from India, is then very cheap to produce and pleases the workers with its durability and comfort. In his book dedicated to the brand Stifel, David Javersak narrates: “The ground floor of the manufactory was dedicated to the printing and the dye. JL Stifel, his wife, and children lived on the top floor.”

Inside out, but booted

In 1835, JL Stifel marries Barbara Becht. The family business continues expanding and in 1859, JL Stifel’s two sons, Louis C and William F, come on board. “The Stifel manufactory was already one of the most important in the country, and the process used by the family already intrigued by its originality”, Rick Morgan explains. In the Stifel factories, the fabric was first soaked in soda to be cleared of all traces of starch and other additives. Once dried, the fabrics were ready for printing. JL Stifel himself was creating the patterns: with his knife, he would cut into wood blocks of maple or pear: small circles, moons, stars…these huge stamps were then applied onto the fabrics before they were soaked in huge tanks of indigo dye. “In 1874, when JL Stifel retired, the manufactory no longer used these big wooden stamps, but a steam-powered process. The company had become the most famous in the country, and its fabrics were going all around the world”, David Javersak explains.

The story goes, at the dawn of the 20th century, the company hires 50 new employees and is forced to move due to limited space and a growing business. Their huge new factory is known all over the country as Calico Works and is run by the third generation of Stifels. It was then that they realized the need for a distinctive symbol that could be recognized all over the world to distinguish their indigo products from others. The decision was made to print a horizontal boot inside the Stifel fabrics; a very logical choice as the word “Stifel” in German means “boot”. “It’s thanks to this small logo that the Stifel products have reached the state of grace in which they are today. When they wanted to prove that they were wearing some original Stifel pieces, workers at the time would wear their clothes inside out, so everyone could see the boot which was printed inside”, tells Rick Morgan, amused by the curious habit.

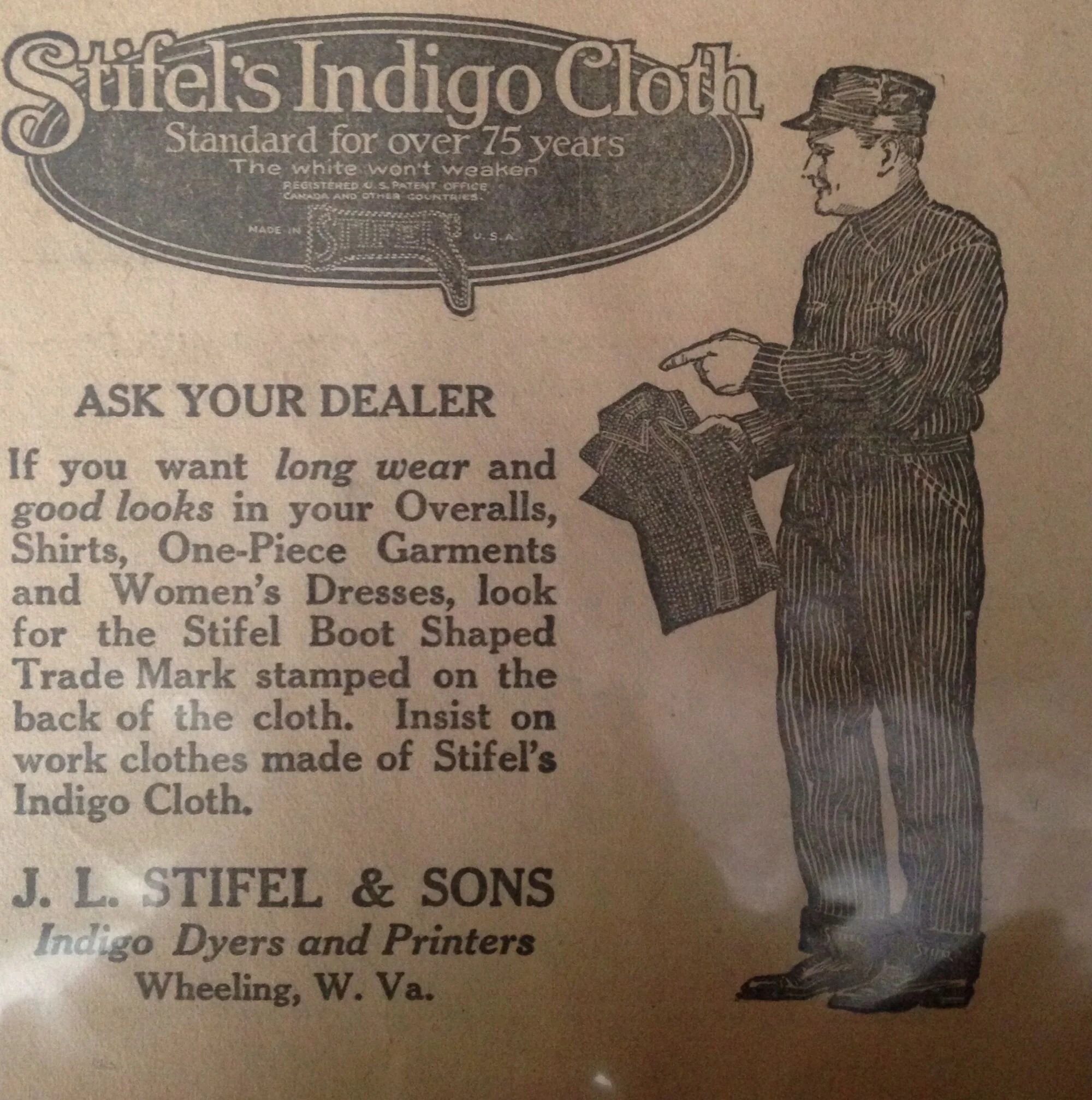

It is also under the care of the third Stifel generation that the brand started playing with the conventions of advertising, with an important particularity: Stifel was not a clothing brand. It would not produce shirts or trousers, but simply a distinctive fabric, which other brands would then use to create articles of clothing. This is without a doubt what makes Stifel the Holy Grail in the eyes of collectors: the small boot is always paired up with another logo: Boss of the Road by Stifel, Crown Overalls by Stifel, Rip-Proof by Stifel, Our Wheeler by Stifel… Everywhere across the United States, clothing shops proudly post up signs reading: “We sell products made from Stifel fabrics.”

Stifel goes to war

The booted brand did not just supply clothing stores. From World War I to the end of World War II, Stifel & Sons had transformed itself into a military production machine. Consquently, it was not rare to find American, Belgian, or French soldiers going into battle covered in Stifel fabrics. “Yes, the French army resorted to the Americans for many of their uniforms, but it remains very complicated to find the exact origin of these uniforms, as the products were delivered in huge batches, and not in retail trade like in a clothing shop”, explains the Museum of the Great War, located in Meaux, France. In the United States, however, a soldier could not ignore where his proudly worn battledress was from. In 1943, at the heart of the war, 90% of Stifel & Sons’ production is contracted out to the military. To recognize their quick production and reliable fabrics, the government honors the company with the Army-Navy Production Award.

Sadly, serving the nation in the best way they knew how was not enough for Stifel & Sons Calico Works to endure the difficult post-war years. In 1957, the company is forced to merge with Indian Head Mills. Only just after the contracts are signed, the booted company’s activities cease for good. On December 17th, 1957, after 122 years of existence, Stifel & Sons Calico Works closes its doors. “The dye, the printing, and our cotton fabrics’ finish can no longer be carried out in an economic and competitive way in the current context”, W. Flaccus Stifel, the last president, tells his employees. “The closing down of the company was already something quite difficult for the town of Wheeling, but it was nothing compared to what the factories would go through a few years later”, Rick Morgan explains. Even worse, on March, 8th, 1961, Stifel’s historical warehouse goes up in smoke during a huge fire. Nowadays, JL Stifel’s descendants still live in the Wheeling area, and the legend surrounding these indigo printed fabrics is still alive in the minds of the most dedicated collectors.

Blue gold prospectors

Once ignored, abandoned, or even thrown away, Stifel products have quickly become masterpieces for all vintage clothing lovers. It must be said that the booted brand still has a lot to offer today in terms of durability and innovation. “What people love about Stifel, is that it really looks like denim but it isn’t. It’s lighter than denim, more elastic”, Hitoshi Yamada, a famous Japanese collector, who owns several Stifel pieces, explains. This hunt for blue gold only started at the beginning of the 2000’s. At that time, collectors were looking for “something fresh, new, something which nobody had in their closet”. So, Hitoshi Yamada and others started to look for Stifel pieces, all unique. “It’s exactly for these types of products that you become a collector. All the prints are different, every model looks unique, it’s a real quest to go after all of them”, explains the man who now has one of the largest collections of rare pieces.

Conceived for workers, the Stifel fabric and all the clothing pieces made with it (jackets, trousers, shirts, overalls) are now sold at huge prices. Furthermore, they are extremely difficult to find, as many have not stood the test of time. “Everyone wants to own a Stifel shirt, with the thin white stripes and original prints”, Takeshi Watanabe, another Japanese collector, who simply uses the nickname “Stifel” on Instagram, explains. “Also, Stifel represents a certain vision of the United States, it’s almost a 19th century stamp. Just look at the old adverts for the brand, it’s vintage, it’s what everyone is looking for.” There is also a certain thirst for challenge that drives collectors from all over the globe to search for the coveted fabric. In fact, it is not always easy to evaluate a Stifel product, as quite often, the small boot does not present itself on the inside of the fabric. Many of these factors make the prices even higher… 500 dollars for a small piece of fabric, 3000 for a jacket, sometimes even more… To Rick Morgan’s big surprise: “At the Stifel Fine Arts Institute, we have a lot of products: JL Stifel’s first stamps, a lot of pieces from the factory, shirts, fabrics… we should maybe think of putting them up for sale to bring a little bit of fresh cash in the bank! (He laughs)” More than just a simple manufactory, Stifel & Sons Calico Works represents a certain idea of the American dream. Its prints and working methods still attracts admiring dyers, and the hunt for blue gold will surely be pursued by collectors for many years to come.

All interviews conducted by Gabriel Cnudde