Solid Rivets and Burrs for Beginners

Want to turn out some handmade gifts ? Rivets may be the key to your newfound creativity. Solid rivets and burrs are the traditional choice and, unlike many modern rivets, are solid metal all the way through. The “burr” acts as a washer which protects the base material and helps hold everything together.

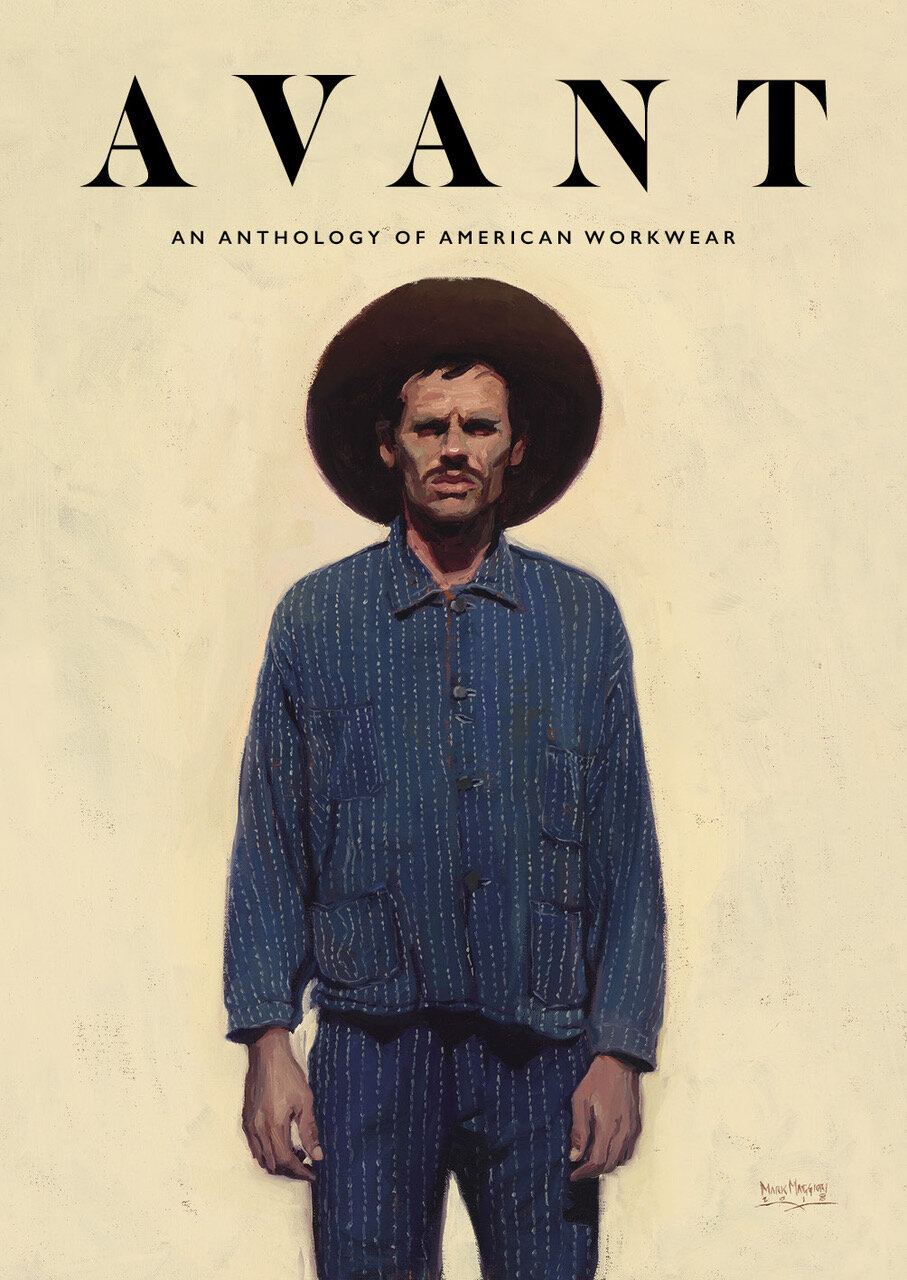

Simple, seamless, and attractive—copper and brass rivets add a touch of ornamentation to all your leather and fabric creations. First, some background. Levi Strauss didn’t invent denim jeans (fun fact). Denim jeans already existed by the 1870s, but it took a tailor from the Nevada goldfields—Jacob Davis—to add riveted reinforcements to the jeans he sold to miners.

The early results were promising. Strauss, being a shrewd businessman and already established in the dry goods business, was intrigued when Davis approached him about a patent. Patents aren’t cheap to research, file, or litigate so Strauss provided the financial backing.

The U.S. Patent Office wasn't sold on the novelty of the idea at first. Their initial response was that riveted reinforcements in clothing were fundamentally no different than riveted reinforcements in leather footwear. The Union Army requisitioned rivet-reinforced brogans in the American Civil War. Strauss and Davis ultimately made their point and the rest is workwear history.

The patent that started it all.

Credits: Google Patents/USPTO.

A riveted brogan as seen in the American Civil War.

Credits: Perry Adams Antiques.

Now on to brass tacks— err, rivets. The two most common rivet materials are classic copper and brass. To the Patent Office’s original observation, these same rivets and burrs can be used in fabric and leather.

What You’ll Need

Credits: @zpliollio/Instagram.

Please keep in mind, that these materials have given me the best results. You may choose different vendors, options, or sizes.

● Solid Copper Rivets and Burrs. The #12 size works for most applications. Typically, the rivets and the burr washers come together in the same box.

● Three-Piece Rivet Set Kit. Remember to pick the set sized to whichever rivets you order.

● Awl or Hole Punch. I recommend using an awl for fabric and a hole punch for leather. Again, the hole size should match the rivet size.

● A “Soft” Mallet or Hammer. Some people may disagree with me here and recommend a regular ball pein hammer, but hear me out. Since the set tools are made of stainless steel–which is softer than most tool steels–it’s a good idea to use a softer hammer or mallet to extend their service life. Brass and rawhide seem to work well. I like the 800-gram or 1-½-pound options.

● Pliers. These provide a way to cut the rivets to length. If they can cut thick electrical wire, they can cut rivets. The sharper the better.

● A Solid Work Surface. This requirement is critical and often overlooked. Nothing is more frustrating than trying to set a rivet and having your kitchen table shake and wobble. You need a stout, clean work surface to do this efficiently and preferably some kind of bench anvil. If you’re really invested in doing solid rivets and burrs, check out a classic lap anvil.

Step 1: Make a Hole.

It's critical not to tear the material you're working with here! In leather, I use a hole punch size that matches the rivet’s “grip”—or long portion—diameter. For fabric, I made a very sharp awl which acts like a giant needle pushing the threads apart and forming the hole. Insert the rivet with the preformed, flat head on the underside of your project.

Credits: @zpliollio/Instagram.

Step 2: Set the Burr.

With the hole formed and the rivet pushed through, it’s time to set the burr washer. I find that my washers have a smooth side and a side with a ridge around the outside—this is a product of the washer being stamped out of sheet metal like a paper-hole puncher. I like the ridges to face down so they will grip the material.

Credits: @zpliollio/Instagram.

Step 3: Cut the Rivet.

Only a few millimeters, or about 1/16 of an inch, of the rivet’s grip needs to protrude above the burr washer. I use a thin piece of leather with a hole punched through it as a template for cutting at the correct height. With a pair of pliers, cut halfway through and then rotate the pliers 90 degrees. This avoids having a sharp v-shaped point on the end of the rivet which helps with the next step.

Credits: @zpliollio/Instagram.

Step 4: Rivet!

This is where the magic happens. Using the tool with the smaller concave face, set the concave portion on top of the cut rivet and start striking it with your mallet or hammer. This essentially presses the rivet back onto itself, forming the head of the rivet with each hit. Just imagine the metal being like clay and the tool is your thumb squashing it against the work surface. The rivet head should appear domed with a smooth top. You did it!

Credits: @zpliollio/Instagram.

Optional Step

The third tool in the set features a wider concave face. If you want to spread the head of the rivet even wider, or you just want a lower-profile rivet, use this tool. Just be careful not to overdo it here. Too much hammering will cause the burr to warp into a dish-shape.

Credits: @zpliollio/Instagram.

Credits: @zpliollio/Instagram.

You’re now ready to work on your personal projects or even gifts! From making belts, wallets, I.D. card holders, and key fobs to personalizing and repairing your denim collection, you can now craft confidently. Solid rivets and burrs have over 150 years of denim history behind them–it’s up to us to keep it going for the next 150 !

Dive deeper into the rugged world of workwear!

Discover the craftsmanship, history, and enduring style behind iconic workwear pieces in our must-have books. Perfect for menswear enthusiasts and vintage lovers, these books are your ultimate guides to heritage clothing.